- URL

Frequently Asked Questions

Frequently Asked Questions

Frequently Asked Questions

(18) Products

We group product reviews by series because products within a series often share ratings, features, and configurations. Typically, size is the only noticeable difference between the products within a series. By grouping reviews in this manner, we are able to provide you with comprehensive customer feedback on each series, as the products within them are remarkably similar. We believe this approach enables you to make more informed decisions by considering the collective feedback and experiences related to a particular series of products.

What is EMI?

EMI (electromagnetic interference) is the transmission of unwanted, external electromagnetic radiation that creates a disturbance within an electrical or electronic device.

Two Major Types of EMI:

Ambient EMI (Radiated EMI): Originates in other devices (TV, radio) or natural phenomena (lightning strikes, solar magnetic storm.)

Power Quality EMI (Conducted EMI): Originates in various kinds of disturbances and inconsistencies in a device’s power supply (voltage spikes/sags, line noise.)

What Polycase Enclosures Protect Against EMI?

SA Series: Constructed from 304 stainless steel, rated up to NEMA 4X.

SB Series: Constructed from 16-gauge carbon steel, rated up to NEMA 4X

AN Series: Constructed from ADC-12 diecast aluminum, rated up to NEMA 6P

AL Series: Constructed from ADC-12 diecast aluminum, indoor use only

EX Series: Constructed from anodized 6063 aluminum (extruded) and ADC-12 diecast aluminum end caps, rated IP66

Polycase offers a variety of metallic enclosures that provide an inherent level of EMI/RFI attenuation. Our metallic enclosures are constructed with non-conductive gaskets resulting in less attenuation compared to enclosures constructed with metallic gaskets that yield a faraday cage. Testing the specific enclosure for required EMI/RFI attenuation is recommended. Plastic enclosures can be modified with special EMI shielding that is applied to the enclosures. Please contact us for additional information or to receive a quote on this process.

Enclosures rated for temporary submersion should meet NEMA 6 or IP67 requirements to be considered safe for use.

Enclosures rated for complete submersion should meet NEMA 6P or IP68 requirements to be considered safe for use.

Polycase offers a complete selection of submersible enclosures for your waterproof electrical or electronics applications.

Rating Definitions:

IP67: Protection from submersion in water with a depth of up to 1 meter (or 3.3 feet) for up to 30 mins

IP68: Protection from submersion in water with a depth of more than 1 meter

NEMA 6: Protection against occasional temporary submersion at a limited depth. Per UL-50, the 6 Temporary Submersion testing is done at a depth of 6' for a 30-minute period.

NEMA 6P: Protection against prolonged submersion at limited depth in water. Per UL-50, the 6P Prolonged Submersion testing is done at a depth of 6' for a 24-hour period.

The ZH Series enclosures have a hinged cover with an optional latch or screw-down cover assembly. But with either cover assembly, the base and cover are attached with a hinge.

The ZQ Series enclosures only offer the screw-down cover style, there is no hinge or latch option.

All enclosures with screw-on covers include the required screws. If you need additional enclosure screws, contact customer service. The internal PCB mounting boss screws are sold separately and are listed on each product's page.

Stock part numbers are our regular catalog of products easily searched on our website. Stock parts are off-the-shelf enclosures available for purchase.

Custom part numbers are enclosures that are modified with CNC machining and/or digital printing & graphics specifically for you, so these part numbers are unique and not found within our regular catalog (custom part numbers start with J-, JG- or G-). Your custom part numbers are found in your account under the "My Quotes & Custom Parts" section.

Polycase uses flame-retardant plastic material for all of our electronic enclosures. Due to the flame-retardant additive in the material, the plating can be spotty and inconsistent. Along with being a relatively expensive addition, the inconsistency renders the plating potentially useless. Therefore, chrome-plating is possible, but not recommended.

First, are you looking for a custom part number or a stock part number? Custom part numbers always start with J-, JG- or G-. If you are looking for a custom part number, it can be found under the "My Quotes & Custom Parts" section of your account. If you still can't find your custom part in your account, contact us as we would be happy to help! If you are looking for a stock part number that you can't find, you are probably looking at a "complete" part number. Most of our products have configurable options, so the page name is different than the complete part number of the final SKU you are looking for. For example, if you are looking for "DC-47FMBYT", the page name is just DC-47F. You can shop with your specific part number by typing it into the search bar and hitting enter, or by using our "quick order tool" and typing in the complete part number. If you still need help finding the product you are looking for, contact us and we would be happy to help.

Only complete enclosures are sold on our website. UL listed enclosures must be sold as complete units. The potting boxes (BF, BX, and TX series) are sold without covers, but the optional glue-on cover is available for purchase.

A popular solution is a process known as solvent bonding, using compounds such as acetone or MEK. The solvent is placed on both surfaces of the parts to be bonded (the outer ridge of the potting box and the inside of the cover). This softens each of the surfaces and causes them to swell. Then, by applying pressure to the two parts and allowing the solvents to evaporate, the two surfaces are permanently bonded. A simpler method is to use Super Glue or any sort of ABS or plastic cement.

Yes, Polycase sells PCB mounting boss screws for all enclosures with internal bosses. The correct PCB screws are listed on the product pages.

Polycase does not supply contacts to wire the VM-Series enclosure batteries In-Parallel. Our contacts are for In-Series. Listed below are part numbers of battery contacts that you can look at to wire the batteries in parallel. You can purchase the contacts from a distributor such as Allied Electronics - www.alliedelec.com

Battery contact manufacturer: Keystone Electronics

part numbers:

5228 dual spring contact

5227 dual button contact

5221 single button contact

5222 single spring contact

Polycase does not offer rubber bumpers for enclosures, with the exception of the EX Series (these are included with purchase for use specifically for the EX Series). Rubber bumpers are commonly available from electronics distributors. When selecting a bumper, choose one where the diameter is slightly smaller than the recessed indentation that you are putting them in.

Polycase’s bone and gray colors are not made to a specific PMS color, or any other color standard. They are color matched to a previous proprietary resin color. Based on a visual comparison to a printed PMS booklet, bone is most similar to PMS 7534 and gray is most similar to PMS Cool Gray 6. Note we recommend referencing these values for graphical design purposes only. These values should not be used if a color match is required for any other components.

Polycase enclosures are available in either aluminum, steel, ABS plastic or Polycarbonate plastic. In general, plastic enclosures will have a reduced recommended operating temperature compared to aluminum and steel. Their properties will change at both low and high temperatures and may no longer be stable. Generally, ABS will have useful characteristics within a temperature range from −20 to 80 °C (−4 to 176 °F), whereas Polycarbonate’s temperature range is from -40°C to 120°C (-40°F to 248°F). However, components of the enclosure (such as a gasket) can still affect the ranges in which the enclosure can operate. Please refer to the ratings (and materials tab) on the product pages for specific details.

There is some bowing that can occur on the walls of the enclosures. This happens as the box cools, after being removed from the molding tool. This is inherent to the design and not considered a defect.

There is a technique that can help you assemble the covers onto the bases. When putting the cover on, put one corner on first and push the cover towards that corner, then press down. This will allow the cover to be easily pressed into place before screwing down.

If you are seeing a convex shaped arc that appears about 1/2" from the bottom of the base, we refer to this as "sunshine." The sunshine does not deform or alter the shape of the box. It is simply an aesthetic characteristic resulting for the design of the box and how the material flows in the mold. While it can vary slightly from run to run, "sunshine" is typical on each part.

The recommended torque on our enclosure screws can be found here.

(6) Ratings and Compliance

Our RoHS declaration can be found here.

Please refer to our REACH statement here.

Our enclosures are not plenum rated.

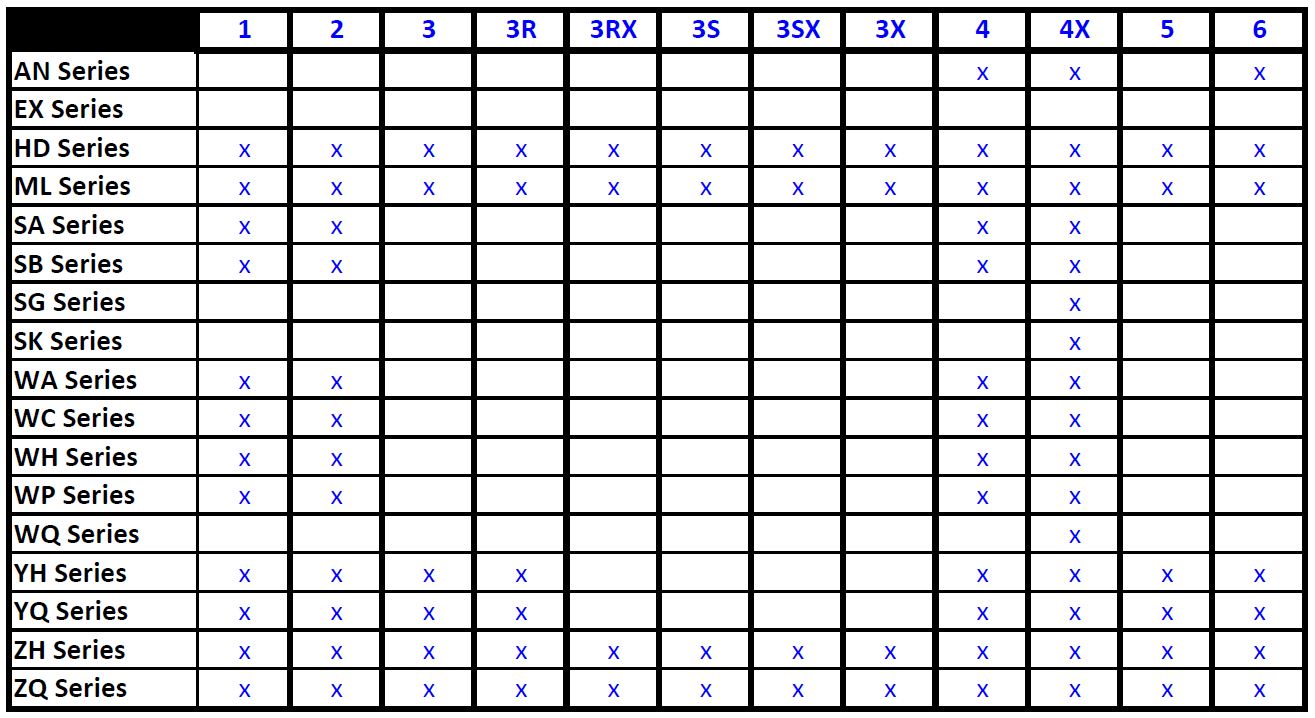

Please see NEMA ratings chart below. UL & NEMA Ratings are based on independent lab testing by UL and/or information available from the manufacturer.

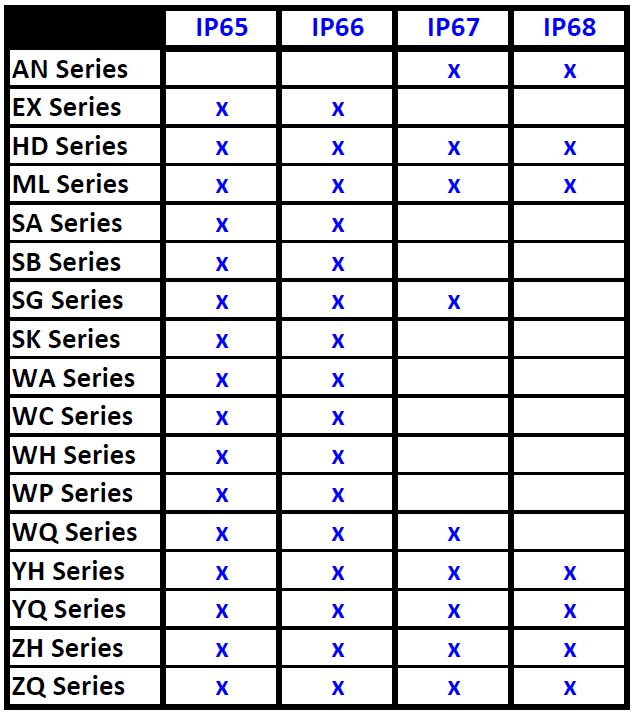

All of Polycase enclosures can be rated IP40, assuming the covers are properly secured. We have several series meeting higher IP ratings per the below chart. Most Polycase IP Ratings are based on the NEMA 250 to IEC 60529 conversion table published by NEMA.org. NEMA Enclosure Types exceed the requirements for the respective IEC 60529 designation. IEC 60529 specifies that an enclosure designated with the stated degree of protection indicated by the first characteristic numeral (IPXX) also complies with all lower degrees of protection. An enclosure designated with a degree of protection indicated by the second characteristic numeral (IPXX) also complies with all lower degrees of protection up to and including the second characteristic numeral 6. An enclosure designated with a second characteristic numeral 7 or 8 is not suitable for water jets (5 or 6) unless it was tested for water jets and is dual coded.

Yes, our Proposition 65 declaration can be found here.

(4) Policies

Polycase is committed to providing the greatest value in the global enclosure market. To ensure that we deliver on this commitment, we keep quality and customer service at the forefront of all decision-making. Our Quality Management System is integrated into every aspect of our business to make sure our customers have a consistently positive experience.

We pair our speed-based model with value-added services and exceptional technical support to exceed our customers’ expectations. We remain agile to respond to customer feedback and market demands and to foster a culture of continuous improvement.

Polycase management actively reviews and holds the organization accountable to quality performance metrics that identify opportunities and enhance our Quality Management System.

Contact a customer service representative to receive an authorized RMA number to return the product. You will be asked for a description of why you are returning the product, PO or invoice number, and total number of parts to be returned. Below are the guidelines for returning product.

Stock parts:

All parts must be returned within 30 days. Polycase will offer credit for parts passing inspection only. No credit can be given for freight. A restocking fee of 20% will be charged. The restocking fee may be waived if placing a new order of equal or greater value.

Modified parts:

No returns accepted. Any customized product is non-refundable, non-cancelable.

*The SA Series (all sizes), WQ-76, WQ-77, WQ-80, WQ-81, WQ-83, SB-52 and SB-54 enclosures are non-returnable*

All shipments should be inspected upon receipt. If parts are defective or modified incorrectly, Polycase must be notified within 6 months of the shipment. As storage conditions may affect part quality, no parts will be refunded after 6 months.

Refer to our shipping information page for more details.

Polycase manufactures and distributes a proprietary line of off-the-shelf enclosures and accessories for use across various industries. Unfortunately, due to the high volume of requests, we cannot respond to individual customer supplier surveys / new vendor forms. However, we can provide you a company profile that includes commonly requested information upon request. We apologize for any inconvenience.

(5) Ordering

Polycase will only charge sales tax on orders shipping to an Ohio address. If you have an Ohio Sales Tax exemption certificate, please email it to [email protected] before placing your order. Once we have your form on file, we can mark your website account tax-exempt.

Custom orders can be placed online from your instant quote summary page. For more details on placing custom orders, see our custom ordering FAQs.

We accept Visa, Mastercard, American Express, and Discover. Or, orders can be prepaid by ACH, check or wire transfer (wire fee may apply). If your company has Net 30 terms with Polycase, orders can also be placed on your terms. To apply for Net 30 terms, contact Polycase customer service at [email protected].

Yes, we ship internationally. With the exception of P.O. Boxes, Polycase has no restrictions on where we ship. Please note, international shipping rates do not include applicable taxes, customs or broker fees. These are the sole responsibility of the customer. We will ship UPS Worldwide Expedited unless you specify a different method. If you would prefer to ship an order on your own UPS, FedEx or DHL account number, it must be provided during checkout. Estimated ship times are based on available flight options and may vary based on weather conditions and remote locations.

Any error in the address that results in a back-charge from UPS is the responsibility of the customer. Polycase will charge these fees back to the customer once we are notified by the carrier. Fees will be charged to the same credit card used on the original order.

(5) Customization Overview

Almost all stock enclosures on our website can be customized and quoted online. You can also quote revisions to your existing Polycase customized enclosures.

The only enclosures we do not offer customization services on are the SA Series stainless steel enclosures, certain sizes of the SB Series steel enclosures and certain sizes of the WQ series enclosures. If the enclosure does not show up in Instant Quote, then we do not customize that specific size.

Our standard lead time for customized enclosures is 3 weeks, but please note that this may be subject to change depending on the availability of imported products. We also offer 1 and 2 week production expedite options. Expedite pricing can be found on your quote.

Visit our 90 second Instant Quote tool to see pricing, generate a quote and place an order for customized enclosures. If you have questions generating your quote, contact Polycase and we will be happy to assist.

The mounting bosses are built directly into the mold. While we cannot change the mold, we can supply the cases without bosses or machine the bosses out. We offer adhesive standoff's so you can place your mounting bosses in the exact location you need.

Alternatively, we can machine countersunk holes in the locations that the bosses are needed. You would then fasten stand-offs to the enclosure with countersunk screws in the machines holes. Then your PCB can be screwed to the top side of the stand-offs inside the enclosures.

We do not offer any custom molding or tool building, we sell off-the-shelf enclosures and we cannot change the shape or size of the enclosures. However, we do offer secondary services to customize your enclosure to fit your needs. We offer CNC machining and digital printing. To learn more about our additional services, visit our customization services page, or get pricing using our instant quote tool.

(4) CNC Machining

Yes, we can machine down the height, or remove, the mounting bosses. Because they are only ¼” tall, often they do not interfere with the desired application, but if they do, they can be machined out or made shorter. Additionally, some of our enclosures are available with or without the bosses.

Because the enclosure covers are created to fit tightly to the enclosure, once the base is machined down the covers will no longer fit. So this is only recommended for potting boxes or applications that do not require a cover.

We can machine any size or shape holes that you needed, on any surface of the enclosure. Polycase design engineers are happy to help you with the design if you need assistance. Based on the board and connectors you use, together we will be able to determine the best locations and sizes of holes that would work for your product.

Polycase can machine virtually any size or shape opening that you may require, however all drawings will be reviewed by Polycase to ensure manufacturability. All square and rectangular cutouts will typically have a minimum corner radius of 0.031" and tolerance on machined features will typically be +/-0.005". These may increase depending on enclosure selected and feature machined. For components we typically recommend sizing your cutouts to be .040" larger than the component (or .020" for round cutouts). Occasionally, certain features may not be able to be machined or will require a non-standard approach which could increase the machining price. This would be determined when the order is placed. Contact Polycase Technical Support if you have specific questions regarding a machined feature.

(5) Digital Printing

Digital printing involves the spraying of ink directly onto the enclosure and then curing with UV light. The printer uses software to manage the image, controlling when the printer releases tiny droplets of ink directly onto the enclosure’s surface. The ink is applied in a specific sequence and pattern that allows the digital image to be accurately recreated. Digital printers have the capacity to print a variety of colors and gradients, but there are some limitations (like neon colors). When digital printing, we utilize specially designed fixtures to ensure accuracy. Because of this, if the enclosure is too large or has a feature that will compromise the print or equipment, we will likely resort to pad printing.

Pad printing uses a plate to transfer ink from the pad to the enclosure. This method only allows one color to be printed at a time, along with only being able to do a single enclosure at a time. The quality between digital printing and pad printing oftentimes does not vary.

The ink used in the digital printing process is UV cured. The adhesion / scratch resistance of the ink on the plastic is excellent. The ink cannot be scratched off of the plastic without mechanically scratching into the plastic itself. Internal cross hatch cut and tape testing resulting in no ink being pulled up after testing was completed.

Furthermore, after internal testing according to UL Standard UL 61010-1 (Electrical Equipment for Measurement, Control, and Laboratory Use, Section 5.3, Durability of Markings), there was no observable degradation in legibility, smearing or fading of the printing after performing the test.

The ink used in our printing process is acrylic based; UV cured, and is an ink system that is used for labels. It's not labeled as UV resistant because it reacts with, and is cured by UV light. However, the ink can be exposed to UV rays. The ink is commonly used in the sign and banner industries which endure heavy UV exposure. As with any ink, the color will fade over time. You may start to see fading in 2-3 years for typical outdoor applications and 3-5 years for typical indoor applications.

Vector based artwork is required. This includes, but is not limited to, Adobe Illustrator, Corel Draw, and .pdf or .eps files.

(ACCEPTABLE ARTWORK FILES CHART/ PDF HERE)

Colors will be printed per your electronic artwork file. Artwork should be designed for the CMYK color space. If a PMS color value is requested, the CMYK equivalent will be printed. There may be a color shift in the process depending on the specific spot color. Black, red, and white are the available colors for keypad printing.

When printing is ordered, graphic file(s) with fonts converted to outlines or curves is suggested. If not converted, any fonts that are used should be sent along with the graphic file(s). If a font is not provided Polycase will use Arial.

Polycase offers full-color digital printing (also referred to as a 4-color process or CMYK) on most surfaces. It can be used for simple text, gradients, blended colors, color transitions, or photo-quality images. Vector based artwork (designed for the CMYK color space) is required for printing. In the unlikely event a surface is not eligible for full-color digital printing, Polycase can pad print. During approval process, Polycase will advise if pad printing will be performed.

(8) Custom Ordering

Learn about what happens after you place your custom order by watching our 60-second clip.

Our standard lead time for customized enclosures is 3 weeks, but please note that this may be subject to change depending on the availability of imported products. We also offer 1 and 2 week production expedite options. Expedite pricing can be found on your quote.

Orders can be placed right from your quote summary page. Drawings and files can be submitted at the time of order, or after the order is placed. But please note your lead time cannot begin until all drawing and/or artwork files are received for the order.

Quotes are saved in your account they can be accessed through the "My Quotes & Custom Parts" link in the "My Account" section after logging in

Yes, a quote can be edited at any time prior to ordering. Once ordered, it is no longer editable.

Polycase values and protects our customers’ privacy. Part of this is protecting our customers’ custom products. In order to purchase a custom product on behalf of your customer, have your customer provide you with the Polycase custom part number, quote number or Polycase drawings. Or your customer can contact us directly to let us know who will be purchasing the product going forward, and to confirm we have their permission to sell this product.

We offer 1 and 2 week production expedite options. Expedite pricing can be found on your quote. (Standard lead time is 3 weeks.)

Polycase production drawings are not created until an order is placed. Once an order is placed, production drawings are created and sent to you for review and approval prior to production.

(6) Instant Quote

Almost all stock enclosures found on the website can be customized and quoted online. You can also quote revisions to your existing Polycase customized enclosures.

The only enclosures we do not offer customization services on are the SA Series stainless steel enclosures, certain sizes of the SB Series steel enclosures and certain sizes of the WQ series enclosures. If the enclosure does not show up in Instant Quote, then we do not customize that specific size.

What is the difference between a new customized enclosure and a revision to an existing custom part?

A revision indicates you have an existing customized part with Polycase (part #'s start J-, JG- or G-) and you need to modify the machining, printing or both for a next generation or new version of the old enclosure. When revising an existing customized enclosure, the previous version is marked obsolete and it can no longer be ordered.

A new customized enclosure is a brand new project that has not been ordered before.

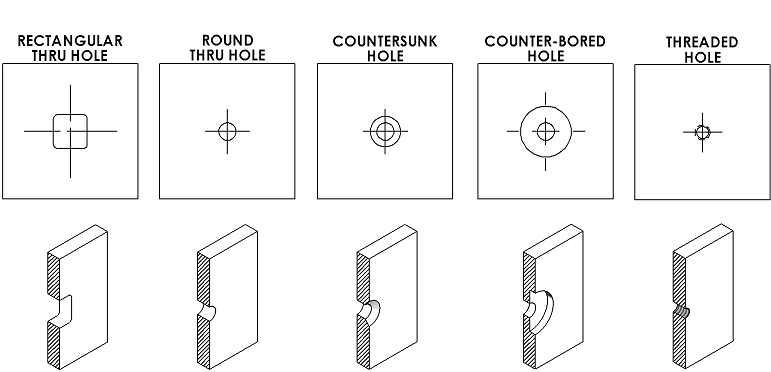

A feature consists of any size or shape through-holes, countersinks, counter-bores, recesses, bevels, taps, screw tower removals, mounting boss removals, or interior wall thinning. For example, a round hole would be 1 feature. A round hole with countersink would be 2 features (1 feature for the through hole, 1 feature for adding the countersink). Counterbored holes and threaded holes would also be considered 2 features. Examples of common features are shown below. Non-standard features can be quoted by contacting Polycase Technical Support.

These are non-recurring charges on your first order for a new or revised project to set-up and create your new customized part (i.e. create custom part numbers, engineering drawings, CNC programs, digital artwork files and printing plates for the enclosures). The charges are applied to first time new and revised orders only.

Quotes are saved in your account they can be accessed through the "My Quotes & Custom Parts" link in the "My Account" section after logging in.

Yes, a quote can be edited at any time prior to ordering. Once ordered, it is no longer editable.

(6) Company Accounts

While Individual User Accounts are great for single users, we highly recommend migrating to a Company Structure when you have multiple users, own a business, or wish to utilize Net 30 terms.

Individual Account Benefits

- Track the status of your order

- Access tracking numbers for shipments

- View order history

- Save custom quotes and order custom parts

- Create project lists and wish lists

- Store secure, tokenized credit card information for quick checkouts

Company Structure Exclusive Benefits:

- Shared access to custom quotes and custom parts between company users

- User management for Company Administrators (add, remove & edit permissions of company users, and create teams)

- Place orders on Net 30 terms (credit approval required)

- +All Individual Account Benefits

- Log in or create an account on our website.

- Navigate to “MY ACCOUNT” in the upper right-hand corner then click “MY DASHBOARD”.

- On the left-hand menu, click “COMPANY STRUCTURE” then use the “Click here” link to access the company registration form.

- Fill out your company information and submit the form to be reviewed & approved by a Polycase team member.

Users can be added from either the COMPANY USERS link or the COMPANY STRUCTURE link.

Under the “ROLES AND PERMISSIONS” link in the Company Structure, you can create roles to limit or grant specific permissions to your company users.

- To create a new role, click “ADD NEW ROLE”, and name the role you are creating.

- Unselect the “ROLE PERMISSIONS” you do not want this role to have.

- Select “SAVE ROLE”, this role can now be given to future and current users within your company structure.

Roles can be assigned multiple ways by a Company Administrator:

- Within the “COMPANY USERS” tab you can click “ADD NEW USER”, then enter in the employee data and select the “role” you wish to give them.

- From the “COMPANY USERS” tab you can also edit users’ roles by clicking “Edit” on the right-hand side of the user in case you wish to change any roles/permissions in the future.

- Within the “COMPANY STRUCTURE” tab you can click “ADD USER”, then enter in the employee data and select the “role” you wish to give them.

- From the “COMPANY STRUCTURE” tab you can also edit users’ roles by selecting a user and clicking “EDIT SELECTED” in case you wish to change any roles/permissions in the future.

A wish list allows for a one-time purchase of items from your list. A project list allows for repetitive purchases of an item, or group of items, from your list. Products can be added to either list from the product’s page. Both wish lists and project lists can only be accessed while logged into your account.

For more detailed information on wish lists and project lists visit our learning center article.

My Quotes & Custom Parts: References only custom quotes & custom parts created under your login information.

Company Quotes & Custom Parts: References custom quotes & custom parts created by other users within the company structure.