- Url

Same Day Shipping

On in-stock orders placed by 3:00pm EST (Monday-Friday)

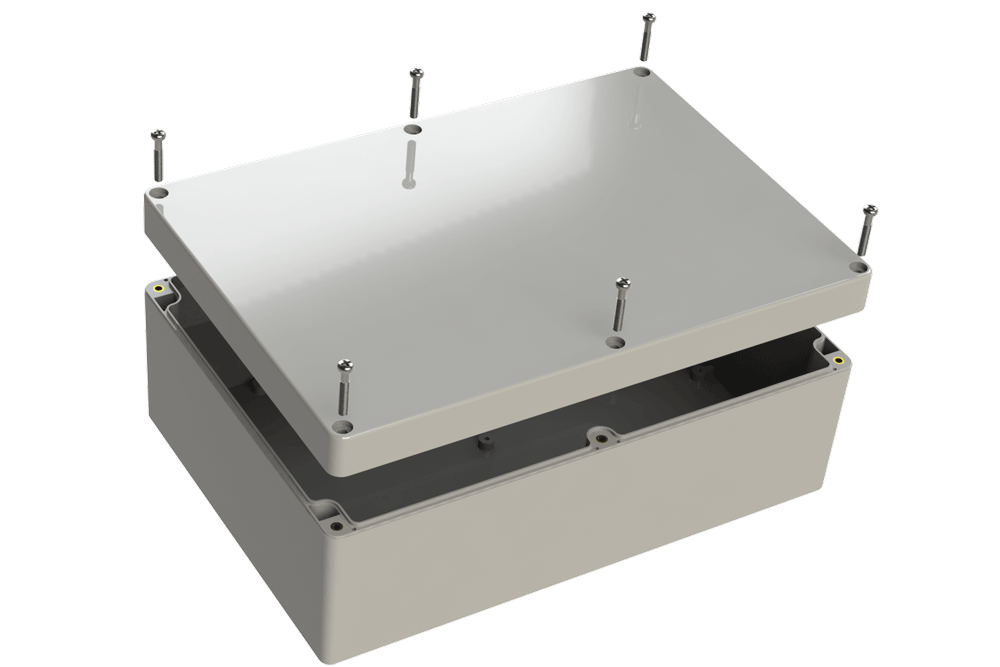

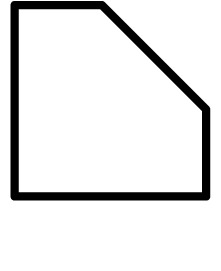

Original

Original Modified

Modified

CNC Machining

Precision modifications tailored to your exact design needs, including cutouts, threaded holes, recesses and more.

Learn More

Digital Printing

Add a professional touch to your device with full-color digital printing applied directly to the surface of the enclosure.

Learn More

Laser Marking

High-contrast graphics that withstand the harshest environments, offering the best in durability and accuracy.

Learn MoreWhy Polycase Customization?

Customers count on Polycase as a trusted partner - backed by more than 30 years of experience, we know what it takes to deliver quality.

![[Customization Services] Why Polycase Section - Slide 1](https://www.polycase.com/media/forix/bannerslider/images/d/a/david_y._review_2.jpg)

[Customization Services] Why Polycase Section - Slide 1

Customer-First Mindset

From expedite options to full price transparency from the start - we want what's best for you and your project.

-

SUPPORT YOU CAN COUNT ON

We work with you to solve challenges, optimize your design, and ensure a smooth path from concept to completion.

-

NO MINIMUM ORDER QUANTITY

We cater to businesses of all sizes, making ordering ideal for prototypes, small runs, or scaling up over time.

-

NO SCRAP COSTS

We don’t charge for parts scrapped during setup. Fine-tuning and setup adjustments are on us, not you.

![[Customization Services] Why Polycase Section - Slide 2](https://www.polycase.com/media/forix/bannerslider/images/c/h/chuck_r._review_1.jpg)

[Customization Services] Why Polycase Section - Slide 2

Single Source Supplier

Take control of your supply chain by eliminating multiple vendors, allowing for fewer steps, faster turnaround, and consistent results.

-

WE'RE THE EXPERTS

Nobody knows our products better than we do. Period.

-

COST & TIME SAVINGS

Avoid additional lead times, shipping charges, labor costs, and time spent dealing with multiple vendors.

-

CONSISTENCY & RELIABILITY

Fixtures designed specifically to hold our enclosures allow for tighter tolerances, and better results.

[Customization Services] Why Polycase Section - Slide 3

Customization Made Easy

Our customization process makes it easy to quote, order and revise your custom project all online.

-

CREATE YOUR QUOTE

Take 90 seconds to create your own quote. Just select the number of surfaces, cutouts/features, and colors - quick, simple, and hassle-free.

-

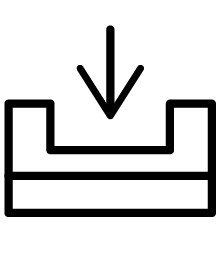

PLACE YOUR ORDER

Add your drawings, choose your quantity and lead time - then simply place your order.

-

PRODUCTION & DELIVERY

Production drawings will be sent to you for approval, once approved we begin production. Parts are then packaged and shipped - ready to assemble when they arrive.

CNC Machining Capabilities & Applications

Precision-machined cutouts for cable entries, display windows and more - expertly handled at our Ohio facility for a wide range of applications.

![[Customization Services] CNC Machining Capabilities - Slide 1](https://www.polycase.com/media/forix/bannerslider/images/s/l/slide_1_4.jpg)

[Customization Services] CNC Machining Capabilities - Slide 1

Basic Cutouts

Create thru holes in virtually any size or shape for a wide range of uses.

-

THRU HOLES

In virtually any size or shape needed to fit your application, thru holes are ideal for cable pass-throughs, buttons, display screens and more.

-

CONNECTORS

Add openings for board mounted hardware and panel mount connectors.

-

VENTILATION & SOUND TRANSFER

Create patterns to enhance visual appeal, sound clarity or to provide effective heat ventilation.

![[Customization Services] CNC Machining Capabilities - Slide 2](https://www.polycase.com/media/forix/bannerslider/images/s/l/slide_2_4.jpg)

[Customization Services] CNC Machining Capabilities - Slide 2

Specialized Hole Types

Machined features designed for enhanced function and ease of installation.

-

THREADED/TAPPED

Add threaded holes directly to the enclosure to simplify component installation.

-

COUNTERBORE & COUNTERSINK

Allow fasteners or connectors to sit flush or recessed below the surface for a clean, secure finish.

-

KNOCKOUTS

Pre-machined partial cutouts that can be removed in the field for flexible wiring options.

![[Customization Services] CNC Machining Capabilities - Slide 3](https://www.polycase.com/media/forix/bannerslider/images/s/l/slide_3.3_2.jpg)

[Customization Services] CNC Machining Capabilities - Slide 3

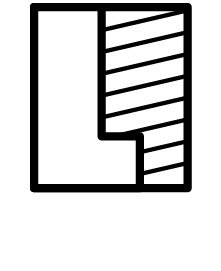

Surface & Edge Modifications

Refine the look, feel or function of your enclosure with edge finishes and surface adjustments.

-

CHAMFERED/BEVELED EDGE

Add angled edges to remove sharp corners, improve aesthetics and LCD viewing angles.

-

RECESSED SURFACE

Lower an external surface area to create a pocket for labels, membranes or components. It can also be used to remove powder coating for grounding.

-

WALL THINNING

Machine the inside wall to add more interior space or simplify component installation.

![[Customization Services] CNC Machining Capabilities - Slide 4](https://www.polycase.com/media/forix/bannerslider/images/s/l/slide_4.3_4.jpg)

[Customization Services] CNC Machining Capabilities - Slide 4

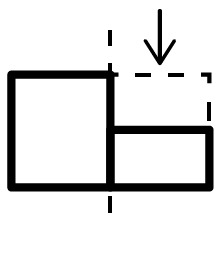

Miscellaneous Modifications

Fine-tune enclosure features with precise, application-specific modifications.

-

MOUNTING BOSS MODIFICATIONS

Modify or remove internal mounting bosses to optimize internal use.

-

RIB REMOVAL

Remove or reduce card guides to simplify the component installation.

-

HEIGHT REDUCTION

Reduce overall height on potting-style enclosures.

Real Projects from Real Customers

Guidelines

TYPICAL TOLERANCE: +/- .005" on hole size and +/- .010" on location (requests for tighter tolerances can be discussed during drawing review stage)

MINIMUM RADII: .031" or .063"

KNOCKOUTS: Knockouts added via CNC machining do not "punch out" similarly to knockout in a stamped enclosure. Instead, there are two options for knockout styles, a tabbed style, and a recessed style. Visit our FAQs to learn more.

DISCLAIMER: Tolerances are dependant on enclosure selected and feature being machined. Not all modifications are compatible for every product, feasibility depends on the specific enclosure and feature.

Requirements

Your machining details/drawings can be uploaded once you've completed your custom quote. Simply add them to the drawings section of your Quote Summary page, during checkout, or after checkout from your account.

ACCEPTED FORMATS FOR CNC MACHINING DETAILS/DRAWINGS

For ease of manufacturing and to ensure compatibility with the manufacturing process, Polycase will generate its own production files from your provided drawings.

Please note: Polycase production drawings will not be created until after an order has been placed.

Graphic Capabilities & Applications

Eliminate the headache of applying stickers and adhesive labels - our graphic services offer a long-term solution that looks professional while saving you time and money.

![[Customization Services] Graphics Capabilities - Slide 1](https://www.polycase.com/media/forix/bannerslider/images/g/_/g_slide_1_1.jpg)

[Customization Services] Graphics Capabilities - Slide 1

Full-Color Printing Capabilities

Artwork, labels, and logos printed directly onto the surface of your Polycase enclosure that won't peel, bubble, or scratch-off.

-

FULL-COLOR CAPABILITY

Print virtually any color within the CMYK spectrum - allowing for bold, eye-catching designs.

-

HIGH-RESOLUTION RESULTS

Graphics that turn out crisp with high levels of detail in gradients, images, and more.

-

OUTDOOR GRADE QUALITY

Resistant to UV-exposure, moisture, and abrasion for lasting performance.

![[Customization Services] Graphics Capabilities - Slide 2](https://www.polycase.com/media/forix/bannerslider/images/g/_/g_slide_2_1.jpg)

[Customization Services] Graphics Capabilities - Slide 2

Laser Marking Capabilities

Alter the material surface with a concentrated beam of light to create crisp contrast graphics or selectively remove surface coatings.

-

DURABILITY

Since the material itself is physically altered, the markings are virtually impossible to remove - making it suitable for all environments.

-

PRECISION

Advanced image processing enables precise alignment around cutouts and features, allowing for exact placement of indicators, labels, and more.

-

COATING REMOVAL

Remove the powder coating found on metal enclosures for graphics, increased conductivity and more.

![[Customization Services] Graphics Capabilities - Slide 3](https://www.polycase.com/media/forix/bannerslider/images/g/_/g_slide_3.jpg)

[Customization Services] Graphics Capabilities - Slide 3

Endless Applications

Everything from simple text to QR codes and serialization to intricate designs and custom branding - our graphic services allow for a wide range of possibilities.

-

ARTWORK & BRANDING

Everything from simple lines and icons to detailed, full-color imagery, gradients, and custom graphics that reflect your brand identity.

-

IDENTIFICATION

Clearly identify buttons, connectors and other components or serialize for part identification.

-

INSTRUCTIONS & INFO-GRAPHICS

Prioritize safety and communication by adding critical information such as warnings, instructions, and diagrams directly to your enclosures.

Real Projects from Real Customers

Guidelines

TYPICAL TOLERANCE: +/- .01" (requests for tighter tolerances can be discussed during drawing review stage)

COLOR LIMITATIONS: We are unable to create fluorescent colors such as neon green, or metallic finishes such as gold, silver, etc. We do not color match, color output may not be exact to that requested.

LOCATION LIMITATIONS: Enclosure features like flanges or hinges may affect color graphic placement - in these scenarios, our team will work with you to find the ideal solution based on your project's needs.

CONTRAST GRAPHICS WITH LASER MARKING: Contrast varies by enclosure material. For example, light grey polycarbonate produces a matte charcoal mark, whereas natural aluminum will result in a light/whiteish colored mark and black ABS will result in a matte tan contrast mark. Best results are on light colored plastics and powder coated metals.

Requirements

Artwork must be provided in vector format with fonts converted to outlines (excluding images).

Your graphic details/drawings can be uploaded once you've completed your custom quote. Simply add them to the drawings section of your Quote Summary page, during checkout, or after checkout from your account.

ACCEPTED FORMATS FOR GRAPHIC DETAILS/DRAWINGS

For ease of manufacturing and to ensure compatibility with the manufacturing process, Polycase will generate its own production files from your provided drawings.

Please note: Polycase production drawings will not be created until after an order has been placed.

Choose sharing option

×We use cookies to ensure that we give you the best experience on our website. To learn more, go to the Privacy Page.

![[Customization Services] Why Polycase Section - Slide 3](https://www.polycase.com/media/forix/bannerslider/images/z/i/zig-zag_graphic_5.jpg)