- Url

CNC Machining FAQs for Enclosures

We offer two types of CNC-machined knockouts—tabbed and recessed—that give you flexibility to create access points in your enclosure only when needed.

Tabbed Knockouts: These cutouts are mostly removed, but a few small tabs of material are left to hold the knockout in place. You can easily clip these tabs on-site to create a full thru hole when necessary.

Recessed Knockouts: These are shallow outlines machined into the enclosure wall, reducing the material thickness (typically to about 0.020") without penetrating it. This creates a “breakaway” area that maintains the enclosure’s waterproof rating until you're ready to punch it out.

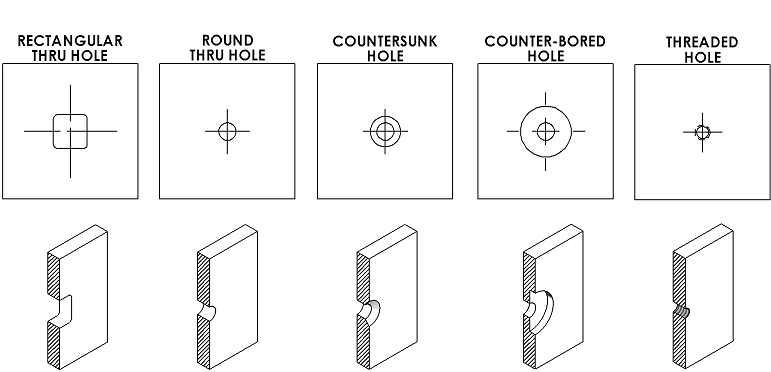

A feature consists of any size or shape through-holes, countersinks, counter-bores, recesses, bevels, taps, screw tower removals, mounting boss removals, or interior wall thinning. For example, a round hole would be 1 feature. A round hole with countersink would be 2 features (1 feature for the through hole, 1 feature for adding the countersink). Counterbored holes and threaded holes would also be considered 2 features. Examples of common features are shown below. Non-standard features can be quoted by contacting Polycase Technical Support.

Yes, we can machine down the height, or remove, the mounting bosses. Because they are only ¼” tall, often they do not interfere with the desired application, but if they do, they can be machined out or made shorter. Additionally, some of our enclosures are available with or without the bosses.

Because the enclosure covers are created to fit tightly to the enclosure, once the base is machined down the covers will no longer fit. So this is only recommended for potting boxes or applications that do not require a cover.

We can machine any size or shape holes that you needed, on any surface of the enclosure. Polycase design engineers are happy to help you with the design if you need assistance. Based on the board and connectors you use, together we will be able to determine the best locations and sizes of holes that would work for your product.

Polycase can machine virtually any size or shape opening that you may require, however all drawings will be reviewed by Polycase to ensure manufacturability. All square and rectangular cutouts will typically have a minimum corner radius of 0.031" and tolerance on machined features will typically be +/-0.005" and these may increase depending on enclosure selected and feature machined. For components we typically recommend sizing your cutouts to be .040" larger than the component (or .020" for round cutouts). Occasionally, certain features may not be able to be machined or will require a non-standard approach which could increase the machining price. This would be determined when the order is placed. Contact Polycase Technical Support if you have specific questions regarding a machined feature.