- URL

Share

The standards of quality for electronics manufacturing continue to increase, so innovation and precision are equally necessary for manufacturers to stay competitive. Innovative products demand high-quality components, and that’s particularly true of the enclosures that house and protect sensitive electronic equipment. To achieve exacting standards of precision and performance, most manufacturers use computer numerical control machining, or CNC machining, to quickly and reliably modify enclosures to spec.

Polycase is proud to offer complete turnkey electronics enclosure solutions, and we offer customized CNC machining for our plastic and aluminum enclosures. Our customers don’t just need quality enclosures — they need them with the exact cutouts their applications call for, and they need them quickly!

Read on to learn more about why our machining capabilities, turnaround times and accuracy make us an industry leader. First, however, let’s quickly get familiar with how CNC machining works, and why it’s such a useful tool in the manufacturing industry.

What Is a CNC Machine?

NC, or numerically controlled, machining is a technique that’s been used for decades to reduce human error and increase precision in manufacturing. In NC machining, a machine operator inserted a punch card to deliver instructions to machine tools. However, the advent of computer automation vastly increased the accuracy available in machining.

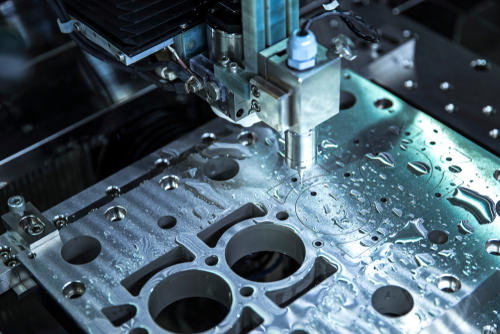

Computer numerical control (CNC) machining is the technique of using computer-controlled machining tools to create and modify parts. The machining process begins with a stock material, called the workpiece, which the machine operator loads into one of the various types of CNC machines, such as a CNC milling machine, CNC router or CNC lathe.

Using a CNC programming language called G-code and any one of various computer programs, a skilled CNC machinist can then send their cutting tools precise instructions for modifying the workpiece. The finished product is cut to spec and produced many times more quickly and cost-effectively than a hand-machined part. It’s today’s gold standard for rigorous, high-performance parts machining for all kinds of applications, from aerospace to automotive and beyond.

Does My Application Require CNC Machining?

If your electronics application demands enclosures with cutouts for cables, wires, controls, vents or just about anything else, our in-house CNC machine shop services can provide the solution. It’s highly cost-effective for producing large numbers of machined parts quickly, but it’s also an efficient way to create small runs for prototyping or DIY projects.

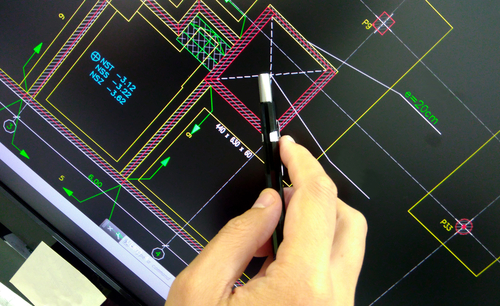

Polycase’s precision machining capabilities employ the latest CNC technology, including computer-aided design (CAD) and computer-aided manufacturing (CAM) software to deliver pinpoint accuracy in custom parts machining. Best of all, we offer these services with fast lead times and with no minimum order requirement.

Advantages of CNC Machining

CNC machining is by far the fastest and most effective solution for ensuring a great fit and outstanding performance for your electronics enclosures. Its numerous advantages include:

- Creating complex parts, including ones that would be virtually impossible for human- or punch card-controlled tools

- Great performance on repetitive tasks — perfect for large runs where the risk for error increases

- Closed-loop CNC machining allows real-time error correction using feedback from the machine tools

How Can I Communicate My Machining Needs?

We accept a wide variety of file formats and drawing types when communicating with our clients on custom CNC machining needs. These include:

- Engineering drawings made using CAD software

- Sketches of the cutouts on our enclosures (PDFs of our products are available on our website for these purposes)

- A specific and exact verbal or written description of the necessary cutouts and where they need to be made

- Sample PCBs, including connectors and mounting hardware to be used, and a specification of which enclosure the PCB is to be mounted to

What Are Your Tolerances and Capabilities?

We offer custom cutouts for hundreds of our electronics enclosure models, using state-of-the-art CNC machine tools. The capabilities of our CNC machining process include:

- Tolerance of +/-0.005”

- Typical minimum corner radius of 0.031”

- Holes of any size or shape on any enclosure surface

- Typical recommended cutout size of 0.040” larger than the component (0.020” for round cutouts)

Some of these characteristics may be subject to change depending on which enclosure you’ve chosen. If you need help designing any aspects of your custom machining solution, our trained staff will be glad to assist you.

Please note that we do not currently offer custom enclosure designs – only modifications to our stock models.

Can You Change the Size of the Enclosures?

Since we don’t offer custom molding, a custom-sized enclosure is not an option. But in some instances, we can reduce the height of our boxes, especially within our potting box series, since they are commonly used in applications that do not require the use of a cover. Machining down the height of enclosures with screw-on covers is typically discouraged since the cover will no longer properly fit on the newly machined edge of the base.

I Don’t Need Custom Machining, Just Knockouts. Do You Offer Those?

Yes, Polycase offers a full line of knockout enclosures. The centers on our knockouts are easy to remove (see our instructions here), and they offer unmatched versatility for onsite equipment installation. Our SK series is an industry-leading knockout box solution perfect for quick installation as junction boxes, control boxes and OEM enclosures. The SK series includes the following features:

- Manufactured from high-quality polycarbonate

- Precision-molded by German OEM manufacturer Spelsberg

- Available for as low as $6.60 per unit

- No specialty equipment required — can be removed with a standard screwdriver

- Available with NEMA 4X and 12K ratings for outstanding water and particulate protection

How Much Can I Expect to Pay?

There’s no need for guesswork! We offer fast and simple custom CNC machining quotes through our Quick Quote tool. In just 90 seconds, you can have a quote for your custom enclosure machining project.

If you’re not comfortable using the online quoting tool, you can send your engineering drawings or a detailed description of what you want to our team at [email protected]. We return most queries within 48 hours.

If you believe your cuts will be more complex than normal, please reach out to us directly using the above email to confirm manufacturability.

What Kinds of Enclosures Does Polycase Offer CNC Machining for?

Polycase serves our customers as a single-source manufacturer of nearly 700 different electronics enclosure models. Our roots are in plastic manufacturing, but we’ve rapidly expanded our line to include state-of-the-art aluminum enclosures as well. We know that our customers have a diverse range of needs, so we offer machining for:

- Extruded Aluminum: Perfect for hobbyists and production manufacturers alike, extruded aluminum enclosures offer slide-incompatibility with standard .063” PCBs. These solid metal enclosures feature diecast end caps and offer the perfect balance of lightweight and outstanding durability.

- ABS Plastic: This tough thermoplastic polymer creates electronics enclosures that are as durable as they are sleek. These enclosures are perfect for indoor and desktop applications where aesthetics are a concern, such as consumer electronics, and are flame-retardant as well. Many of our models offer surface mount flanges, and when you add in our custom CNC machining capabilities, the possibilities are vast.

- Diecast Aluminum: These industrial-grade enclosures set a new standard for performance in professional applications of all types. They offer a natural level of RFI/EMI shielding, and are available in a wide range of NEMA and IP certification levels. We offer both waterproof and non-waterproof models.

- Waterproof Enclosures: For environments where water exposure is a serious concern, such as marine and food service applications, we offer a wide range of electronics enclosures with waterproof qualities. If you need NEMA- or IP-certified water-resistant enclosures, our selection offers unmatched versatility and durability. We also offer waterproof cable glands and venting.

These are just a few of the most popular options from our extensive line of hundreds of products. Our enclosures come in many other different materials, and we offer customized CNC machining for many of them.

What Are Your Minimum Order Quantities?

We pride ourselves on offering no minimum order requirements, which means you can order as little as one customized enclosure from us. We offer this service because it makes our products more accessible to small businesses and hobbyists, who often are unfairly penalized by the business practices of big distributors. If you need a prototype for your product design process or a small order for your hobby project, we’re glad to help.

How Long Are Your Lead Times?

Our standard lead time is three weeks. But if you need your custom machined parts sooner, you can expedite your order to two weeks or even one for a small fee.

Need parts sooner than one week? We may still be able to help. Contact us for more information.

Do You Offer Any Other Customization Services?

Yes! We offer high-quality digital printing on our enclosures, with single-color and full-color options available. Forget wasting time with peeling-prone adhesive labels or cracking and bubbling from poor-quality printing. We print directly onto the enclosure with an extensive array of brilliant, attractive color options.

Why Polycase?

There’s no shortage of competition for electronics enclosures. That’s why we have to make sure we give our customers something our competitors can’t:

- Experience: We have more than 65 years of continuous expertise in manufacturing the best electronics enclosures anywhere. We’ve seen the technological landscape evolve for decades, and we’ve accomplished what others couldn’t by evolving along with it. There’s simply no substitute for the wealth of accumulated knowledge we bring.

- Direct to the Customer: Unlike other manufacturers whose products flow through one or more distributors before reaching the customer, we sell directly to manufacturers, universities and hobbyists. This allows us to keep prices low and provide personalized service.

- One-Stop Shop: If you’re building electronic devices, you’re already likely dealing with a complex and multi-step process. Polycase can help make it just a little bit simpler with our one-stop shop. You can get printing, machining and enclosures all at once!

- No Scrap Costs: We absorb any scrap costs incurred during our manufacturing process. This helps us to deliver reliable and consistent pricing to our customers.

- User-Friendly Service: We offer PDF and CAD files of our products on our website, so you can design your own custom machining plans and we can give our users fast and accurate quotes directly from our website. At every level, we strive to be quick, transparent and user-friendly.

We’re committed to providing turnkey electronics enclosure solutions and to making sure our customers don’t have to shop around. Don’t bother with quotes from machining companies that may require long lead times, unreasonable costs or high minimum orders. To get started with a quote from Polycase, just use our easy and effective Quick Quote tool to find out what you can expect to pay.

Remember, all you need to get started is:

- The type of enclosure you want

- An AutoCAD model, engineering drawing or even just a detailed description of the cutouts you need

- 90 seconds to use our Quick Quote tool

Ready to get going on your customized CNC-machined enclosure? Jump on Quick Quote to get started. We’re looking forward to working with you!

0 Comment