- Url

Share

Put two pieces of differently graded stainless steel side by side and, in most cases, the naked eye will never be able to tell which is which. But at a molecular level, there’s a substantial number of differences, and these differences can be extremely important to understand when you’re choosing stainless steel materials for your project.

For people selecting stainless steel materials, especially stainless steel enclosures, the question of 304 vs. 316 stainless steel is often among the most important ones to answer. These are two common grades of stainless steel which share many characteristics, but also have some unique advantages that set them apart from the other. So, what is 304 stainless steel, what is 316 stainless steel and what are the major differences between the two?

In this article, we’ll compare 304 vs. 316 stainless steel head-to-head. Our guide will examine the unique properties of both 304 and 316 stainless steel, plus the essential facts you need to know to determine which you should choose. And, of course, we’ll look at Polycase’s gold standard for stainless steel enclosures, the Polycase SA Series.

Introduction to Stainless Steel

You’ll be able to understand the different types of stainless steel better if you have a basic comprehension of the materials and processes used to make stainless steel. So, in this section, we’ll offer a quick primer on the composition of stainless steel and the properties that make it such a useful material.

All grades of steel are made from iron and carbon, alloyed with other metals. Stainless steel is steel with certain elements added to it with the purpose of creating various desirable properties that improve on the performance of standard carbon steel. The special properties of stainless steel include:

- Corrosion Resistance: Stainless steel is more resistant than carbon steel to corrosion from saltwater and corrosive chemicals.

- Strength and Hardness: Many types of stainless steel have a higher tensile strength than other common metals, as well as a higher general durability and resilience.

- Temperature Resistance: Stainless steel tends to be more resistant to both high and low temperatures than other types of steel.

- Low Maintenance: Stainless steel requires less maintenance than many other types of materials.

- Elegant Appearance: Stainless steel has a brilliant shine that looks elegant and professional in almost any setting.

Chromium is the most important element in stainless steel, and all stainless steels must contain at least 10.5 percent chromium, usually more. Chromium gives stainless steel its corrosion resistance by forming a chromium oxide coating on the outer surface of the steel that helps prevent rust. (It also creates stainless steel’s distinctive shine.)

However, steel manufacturers also often add elements, such as nickel and molybdenum, to their stainless steels to provide additional protective qualities. These additional alloy elements make a substantial difference in the performance of stainless steel, including between 304 and 316 grades.

To learn more about stainless steel and how it acquires its unique properties, read our guide to carbon steel vs. stainless steel. Next up, we’ll learn about some of the different classifications of stainless steel.

Understanding the Types of Stainless Steel

Different types of stainless steel have different characteristics and strengths. The three major types of stainless steel are:

- Austenitic: High chromium content plus nickel and/or molybdenum; extremely resistant to corrosion. The most common type of stainless steel.

- Ferritic: High chromium content with little or no nickel content; possess magnetic properties and are easier to cut and form. Second most common type of stainless steel.

- Martensitic: High chromium content with relatively high carbon content; extremely hard and durable. Least common type of stainless steel.

304 and 316 are two different types of stainless steel, but both fall into the austenitic stainless steel category. Austenitic stainless steels have internal crystal structures called austenites which give them their incredible strength and corrosion resistance. Now that we know a little more about stainless steel, in the next two sections, we’ll get more specific about the properties of both the 304 and 316 grades.

Basics of 304 Stainless Steel

- Basic Attributes:

- Strong resistance to corrosion

- High durability and hardness

- Excellent heat and cold resistance

- More weldable and workable than other types of stainless steel

- Most easily available and least expensive austenitic steel

- By the Numbers:

- Melting Point: 1400-1450°C

- Tensile Strength: 515-620 MPa

- Yield Strength: 205-310 MPa

- Max Service Temperature in Air: 870°C (intermittent), 925°C (continuous)

- Density: 7.93 g/cm3

- Typical Composition:

- 18 percent chromium

- 8 percent nickel

- Frequently Used for:

- Food service and kitchen hardware

- Commercial and industrial fasteners

- Piping and fittings for plumbing

- Architectural elements

- Heat exchange devices

- Outdoor electrical enclosures

304 stainless steel is by far the most common type of stainless steel available on the market today. In fact, 304 stainless steel makes up over half of the world’s stainless steel supply. That’s because 304 stainless strikes an excellent balance between price and performance. Its substantial anti-corrosion properties and extreme durability combine to make it the standard choice for many applications, and it’s relatively easy to work into a variety of forms, including durable electrical enclosures to protect sensitive equipment.

Thus, 304 is also the stainless steel you’ll find used in the widest range of everyday applications. From kitchen sinks to industrial control boxes, 304 stainless steel is the industry standard choice in many different sectors.

Order Your Stainless Steel Enclosure Today!

Basics of 316 Stainless Steel

- Basic Attributes:

- Extreme resistance to corrosion

- High durability and hardness

- Excellent heat and cold resistance

- Molybdenum content can interfere with workability

- A slightly more expensive and specialized austenitic steel

- By the Numbers:

- Melting Point: 1378-1390°C

- Tensile Strength: 515-620 MPa

- Yield Strength: 240-415 MPa

- Max Service Temperature in Air: 870°C (intermittent), 925°C (continuous)

- Density: 8.03 g/cm3

- Typical Composition:

- 16 percent chromium

- 10 percent nickel

- 2 percent molybdenum

- Frequently Used for:

- Marine equipment

- Chemical storage and manufacturing equipment

- Oil and gas extraction equipment

- Medical equipment

316 stainless steel is another type of stainless steel popular in applications requiring hardness, durability and corrosion resistance, but it tends to have more specialized and limited uses than 304 stainless steel. The most notable property of 316 stainless steel is its extreme resistance to corrosion, particularly corrosion from chloride sources, such as seawater and many industrial chemicals.

The anti-corrosion properties that set 316 steel apart come from the inclusion of molybdenum in its composition. These properties make 316 the preferred choice for a few specific applications requiring extreme resistance to corrosion. Such applications include heavy duty marine projects and industrial applications where the steel will frequently come in contact with harsh, corrosive substances.

Comparing 304 vs. 316 Stainless Steel

Now it’s time for the big matchup: 304 vs. 316 stainless steel. First, note there are various sub-grades of both 304 and 316 stainless steel, and performance ratings vary between them. With that said, let’s take what we’ve learned and organize it into a head-to-head comparison of these two types of stainless steel:

- Cost: 304 stainless steel is usually available for a lower cost than 316 stainless steel. 316 stainless steel is a specialty product used for specific purposes and its manufacturing process is more complex, both of which increase its cost. 304, by contrast, is the standard stainless steel in most industries and is widely available at a lower cost.

- Durability and Hardness: Both types of stainless steel are extremely hard and durable. When it comes to tensile strength, the two are almost identical. The yield strength of 316 stainless steel is higher, but the difference is relatively small. When hardened through cold working, both 304 and 316 stainless steel can achieve considerably higher hardness and strength ratings.

- Corrosion Resistance: This is where 316 stainless steel shines most brightly. 316 stainless steel is more resistant to corrosion, especially from chlorides, than 304 stainless steel. That makes it a common choice for marine equipment and other applications in which the material is exposed to extremely high concentrations of chlorides or other oxidation agents. However, 304 stainless steel still offers excellent corrosion resistance, so this is typically a factor only in marine environments and other high corrosion locations.

- Temperature Resistance: 304 and 316 stainless steel are again quite similar when it comes to high temperature performance, with the same maximum service temperatures for both intermittent and continuous use. 304, however, has a slightly higher melting point.

For most applications, especially where electronics enclosures are concerned, there will be functionally no difference between 304 stainless and 316 stainless. That means the difference will often ultimately come down to price, where 304 stainless steel has an unambiguous advantage.

The Bottom Line: 304 stainless steel is a highly versatile material suitable for most applications, and choosing 304 steel will almost always come with substantial cost savings. While 316 stainless steel is also a versatile and high quality grade of steel, 304 stainless steel will meet most needs unless your application requires extreme corrosion resistance. This ideal blend of cost and performance is why Polycase constructs our SA Series stainless steel enclosures from 304 stainless steel.

Need an Underground Junction Box? Check Out Our Options!

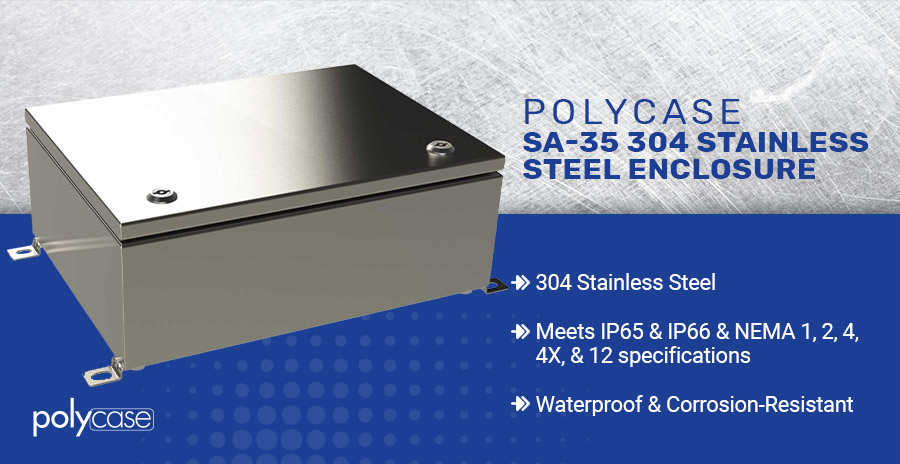

The Polycase SA Series: 304 Stainless Steel Performance

Stainless steel is commonly used to make the electrical enclosures that protect electrical and electronic devices. We construct our Polycase SA Series from 304 stainless steel because of its extreme resistance to environmental hazards which allows these enclosures to protect against harsh environmental conditions, such as wind, rain, dust, hose-downs, splashing water, corrosion and almost anything else you can think of.

SA Series enclosures are NEMA 4X rated and IP66 rated for outdoor grade weather protection. Other major benefits of the Polycase SA Series 304 stainless steel enclosures include:

- Easy to mount, thanks to a built-in set of mounting feet

- Wide range of size choices makes it simple to find an enclosure that fits your size needs

- Secured against unauthorized access by a built-in keyed lock and hinged latch

- Designed to shield your devices from radio and electromagnetic interference

- All-in-one package that includes essentials like a mounting panel and hardware to make setup a breeze and reduce the need to order additional components

The SA Series is an industry-leading option for applications requiring tough NEMA 4X enclosures without sacrificing looks and ease of use. These enclosures can excel in nearly any role, from an underground junction box to a control panel for manufacturing equipment.

See our guide to stainless steel enclosure applications to find out more about the versatility of these high-performance enclosures. And if your enclosure application doesn’t require stainless steel, remember we also offer our high-performance Polycase SB Series carbon steel enclosures.

Polycase’s enclosure experts are always happy to answer questions about our materials, process, products, and more. Contact us at 1-800-248-1233 to speak to our customer service professionals or get a fast and easy instant enclosure quote online.

Image Credits

Jantima14 / Shutterstock.com

Alexandru Rosu / Shutterstock.com

studiovin / Shutterstock.com

horiyan / Shutterstock.com

0 Comment