July 7, 2023

- Url

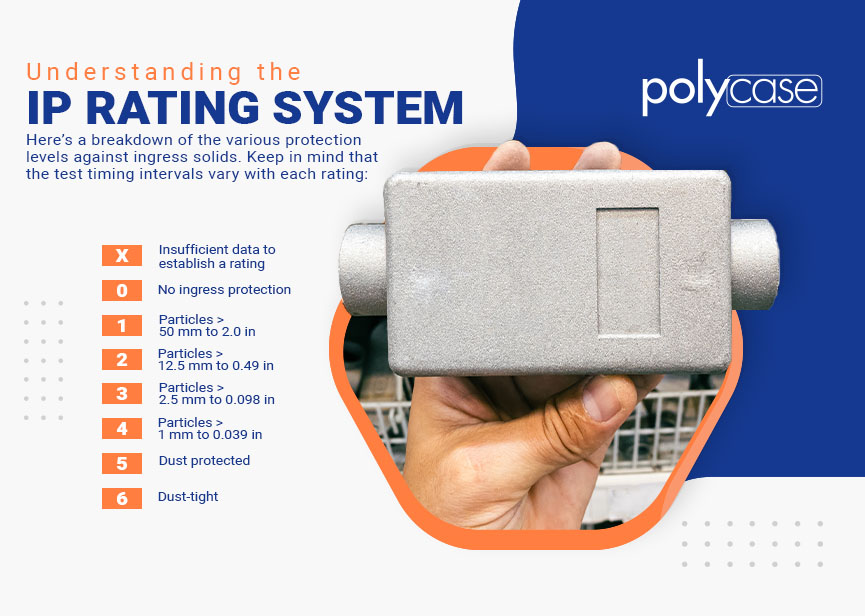

Here’s a breakdown of the various protection levels against ingress solids. Keep in mind that the test timing intervals vary with each rating:

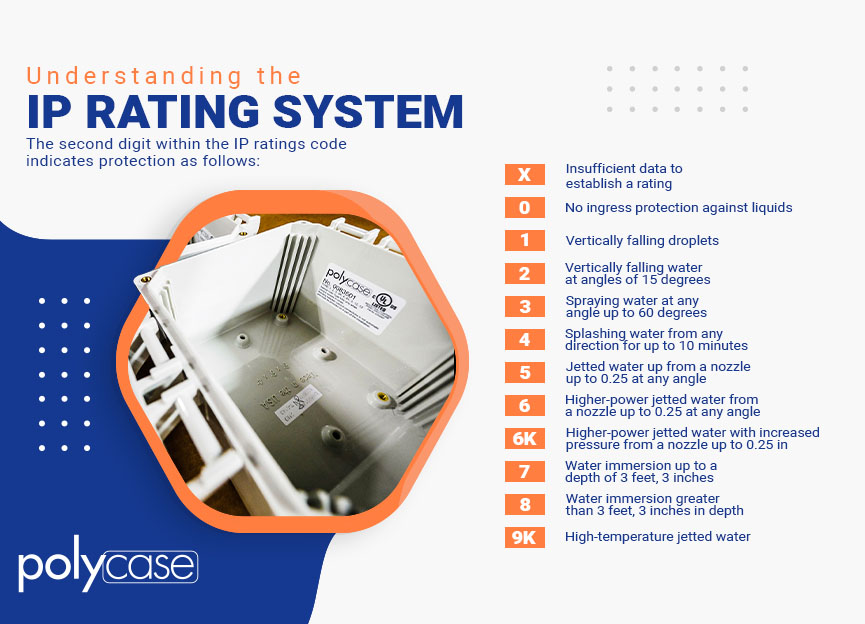

Here’s a breakdown of the various protection levels against ingress solids. Keep in mind that the test timing intervals vary with each rating: The second digit within the IP ratings code indicates protection as follows:

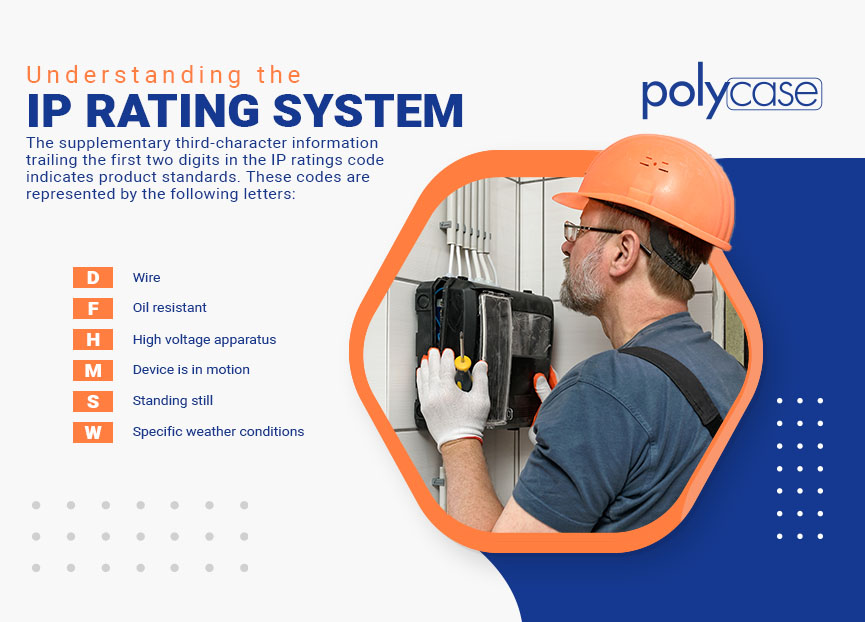

The second digit within the IP ratings code indicates protection as follows: Lastly, the supplementary third-character information trailing the first two digits in the IP ratings code indicates product standards. These codes are represented by the following letters:

Lastly, the supplementary third-character information trailing the first two digits in the IP ratings code indicates product standards. These codes are represented by the following letters: The IP55 rating is relatively common across many business and industrial settings. It safeguards against the ingress of foreign objects that lead to faulty products and worksite hazards. This rating helps engineers prevent potentially damaging particles from entering and compromising the operation of the machinery and factory outcomes. The IP55 rating similarly provides protection against water spraying out of a nozzle from any direction.The IP65 rating is significantly more robust and offers increased protection against dust intrusion, so you can expect considerably reduced dust particles entering into your equipment. The IP65 grade, likewise, provides protection from fast-flowing, pointed jets of water from virtually any direction. The rating is, therefore, most suitable for use in damp or humid environments, such as a factory floor that may experience regular hosing down or other forms of intense moisture.You’ll likely encounter both ratings labeled on various products and materials, including steel, stainless steel, plastic and aluminum.Check Out Our Selection of Waterproof Boxes

The IP55 rating is relatively common across many business and industrial settings. It safeguards against the ingress of foreign objects that lead to faulty products and worksite hazards. This rating helps engineers prevent potentially damaging particles from entering and compromising the operation of the machinery and factory outcomes. The IP55 rating similarly provides protection against water spraying out of a nozzle from any direction.The IP65 rating is significantly more robust and offers increased protection against dust intrusion, so you can expect considerably reduced dust particles entering into your equipment. The IP65 grade, likewise, provides protection from fast-flowing, pointed jets of water from virtually any direction. The rating is, therefore, most suitable for use in damp or humid environments, such as a factory floor that may experience regular hosing down or other forms of intense moisture.You’ll likely encounter both ratings labeled on various products and materials, including steel, stainless steel, plastic and aluminum.Check Out Our Selection of Waterproof Boxes Consider, as well, the desired shelf life of the equipment you intend to install. An IP55 rating offers suitable protection against dry matter, but the IP65 rating does an even better job under more intense conditions. Both ratings can extend the useful life of your machinery because they safeguard against water and are effective in environments where moisture and condensation pose risks.However, if your equipment is subject to intense jetted water or even water submersion, you may need to pursue an IP moisture rating of 7 or 8. Nevertheless, depending on the lifetime desired for the equipment, either IP55 or IP65 should be suitable for most industrial applications. For an outdoor solution, consider using an IP65-rated ZH series enclosure for optimal weather and dust protection.Worksite safety levels are always a concern when choosing between an IP55 and an IP65 rating. Both provide similar levels of defense. However, depending on your application, you may require increased dust protection so that your equipment doesn’t fail. Machinery installed in hazardous environments must have the correct rating to guarantee worker safety. While it’s important to assess the environment, selecting the correct IP rating helps you maintain an optimally safe worksite.These are just a few primary factors to consider when choosing between an IP55 and an IP65 rating. Remember to start with your environmental conditions before looking at equipment lifespan and evaluating worksite safety concerns before making a final decision. When you account for these three main considerations, you’re all but assured to choose the right rating to protect your equipment and personnel from damage and worksite injury.

Consider, as well, the desired shelf life of the equipment you intend to install. An IP55 rating offers suitable protection against dry matter, but the IP65 rating does an even better job under more intense conditions. Both ratings can extend the useful life of your machinery because they safeguard against water and are effective in environments where moisture and condensation pose risks.However, if your equipment is subject to intense jetted water or even water submersion, you may need to pursue an IP moisture rating of 7 or 8. Nevertheless, depending on the lifetime desired for the equipment, either IP55 or IP65 should be suitable for most industrial applications. For an outdoor solution, consider using an IP65-rated ZH series enclosure for optimal weather and dust protection.Worksite safety levels are always a concern when choosing between an IP55 and an IP65 rating. Both provide similar levels of defense. However, depending on your application, you may require increased dust protection so that your equipment doesn’t fail. Machinery installed in hazardous environments must have the correct rating to guarantee worker safety. While it’s important to assess the environment, selecting the correct IP rating helps you maintain an optimally safe worksite.These are just a few primary factors to consider when choosing between an IP55 and an IP65 rating. Remember to start with your environmental conditions before looking at equipment lifespan and evaluating worksite safety concerns before making a final decision. When you account for these three main considerations, you’re all but assured to choose the right rating to protect your equipment and personnel from damage and worksite injury.

ZH-040404 Hinged NEMA Enclosure