- URL

Share

Today, our electronics are smaller, sleeker and more sophisticated than ever before. They also generate a greater amount of internal heat, which poses a serious risk to your electronics if you don’t have a proper method of dissipating the heat.

When heat can’t escape from an instrument enclosure, it can potentially reduce the lifespan of your electronics and even damage them beyond repair. To avoid this costly mistake, it’s important to ensure that your instrument enclosure is properly ventilated.

Polycase has a variety of ways to ventilate your instrument junction box. Whatever kind of custom cutouts, cable glands, or other ventilation solution you require, we’ve got you covered.

Applications for an Instrument Junction Box

From the pharmaceutical and medical industry to testing and monitoring systems, instrument enclosures are used in a wide range of applications. Designed to provide reliable protection for electronic devices, desktop and handheld enclosures play an essential role in keeping critical electronic instrumentation devices running smoothly.

Applications for instrument enclosures are readily found in the scientific community. From sleek enclosures designed to house laboratory equipment and control panels, to rugged instrument enclosures built to protect testing and monitoring field devices , these applications demand reliable protection for sensitive instruments.

With the right venting solution, instrument enclosures can remain cool and running efficiently in a variety of environments. No matter what kind of instrumentation your enclosure includes, the following tips will help you understand the best way to ventilate your instrument junction box.

Calculating Thermal Rise in Instrument Enclosures

Before we discuss venting options, let’s talk about how to calculate the thermal management needs for your junction box. The right calculation process will take all of the relevant factors into account, from the materials of the enclosure to the enclosure size and surface area.

It’s important to note that detailed calculations should always be used when working with large, high-heat electronics. The best way to achieve the necessary precision is by using heat transfer software or with the guidance of an enclosure manufacturer. This is critically important for applications that involve heavy industrial control panels, hazardous areas, large numbers of terminal blocks, or other circumstances in which heat management is a major challenge.

However, most low-powered applications don’t need stringent calculations. Instead, you can calculate an estimate of your instrument enclosure’s ability to dissipate heat and then choose a venting solution based on your findings. To get a ballpark estimate of your instrument junction box’s heat management requirements, read our guide to calculating temperature rise inside a junction box.

Note: Once you have your estimation, remember to use a safety margin to account for variations in both internal and ambient temperatures.

Moisture Management in Instrument Enclosures

It’s also important to consider how you’ll regulate moisture inside your instrument junction box. When moisture accumulates inside an instrument enclosure, it can have severe negative effects.

Ventilation matters as much for moisture management as it does for heat. A well-ventilated enclosure helps prevent moisture from lingering inside the junction box. Vent plugs are particularly popular because they provide excellent airflow while using their ultrasonically welded membrane to keep moisture out.

Choosing an enclosure with a waterproof IP rating, such as an IP68 enclosure, is another good way to help prevent the accumulation of moisture inside your junction box. If moisture is a major concern in your environment, remember that it might also be important to choose an enclosure with a NEMA 4X rating for corrosion resistance.

Need more info on moisture management solutions? See Polycase’s guide to how to prevent moisture in electronics.

Breather Vents and Louver Vents

Breather vents and louver vents provide ventilation for the instrument enclosure by allowing air to pass through naturally, equalizing pressure and reducing condensation. The cooler air passes through, airing out the instrument enclosure and allowing heat to dissipate.

An added benefit to these electrical enclosure venting accessories is that they block liquid and dust particles from entering the enclosure. And with no operating cost, they’re also relatively inexpensive.

However, the downside to breather and louver vents is that they don’t dissipate a large amount of heat. It’s also difficult to predict ambient temperature drops if your enclosure isn’t in a temperature-controlled environment.

Cooling Fans and Blowers

Most low-power dissipations utilize natural convection to dissipate heat. However, high-power dissipations often use forced ventilation by way of fans and blowers.

In larger sealed enclosures, fans can be used to distribute the heat equally so as not to have too high heat concentrations in the enclosure. However, circular fans can’t dissipate the heat in sealed enclosures because there is no way for the heat to escape.

Most sealed instrument enclosures are not large enough to warrant a fan, but circular fans can be used to dispel heat in unsealed instrument enclosures.

Custom Cutouts

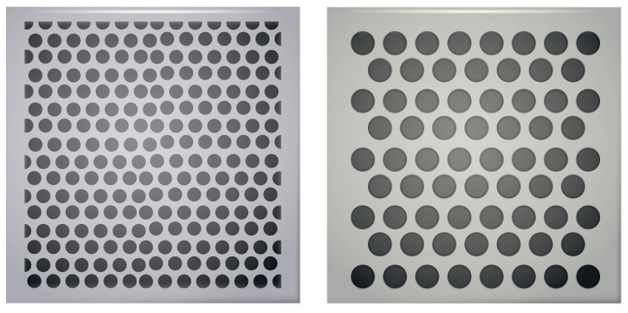

In addition to venting accessories for instrument enclosures, we also provide CNC machining services to create machined slots for ventilation. Using the latest CAD/CAM automation technology, we can produce CNC machine cutouts of nearly any size or shape to any surface with extreme accuracy.

With precision cutting, we can create a custom venting solution built to your CAD specifications. Custom CNC machine cutouts also allow you to control the aesthetic design of your venting solution.

When using this option, here are some things to keep in mind:

- Polycase will monitor the number and placement of holes relative to the material thickness of the enclosure. Depending on your design, cutting too many holes into thin sheet metal may cause it to warp. In this case, we could simply work with you to design larger slots that will provide sufficient cooling without the danger of warping.

- Not all enclosure materials can accommodate custom cutouts. Stainless steel enclosures, for example, are too hard for standard machining tools to cut. However, we offer other metal instrument junction boxes, including our AL Series aluminum enclosures, that accommodate ventilation cutouts well.

- Make sure that your cutouts don’t affect the NEMA rating or IP rating of your junction box. To maintain the same level of ingress protection for your devices, you might need to use enclosure accessories. Cable glands and gland plates are a popular choice for protecting cable entries and connectors on your instrument enclosure.

Importance of Ventilation

All custom instrument enclosures need to allow for the safe passage of air and heat. Without proper ventilation, the life and operation of your electronics will be reduced. By considering these venting options, you can safely dissipate heat and safeguard your electronics from thermal buildup.

0 Comment