I drive a certain patch of freeway to work. 80% of the time there’s a cop waiting with radar gun pointed at traffic. We all know there’s a very good chance he’s there every time we drive past, and still my fellow drivers slam on their brakes when they spot him. But we all push the limits of what we know we should (or should not) do, because we get away with it. When something bad happens, you learn quickly not to do that again, right?Well I’m going to try to prevent you from learning the hard way that plastic boxes have a limit too, on temperature. While some plastic materials have a higher temperature rating than others, regardless what the rating is, once you reach that temperature you are risking deformation and loss of integrity.

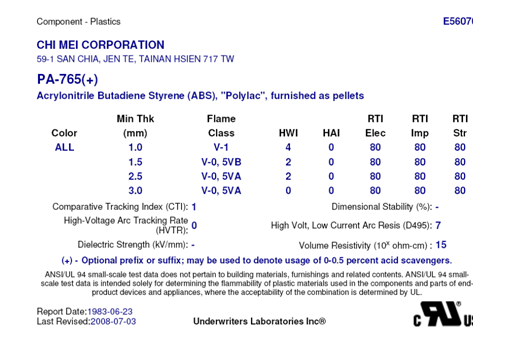

RTI - Relative Thermal Index RTI (formerly known as CUTR - Continuous Use Temperature Rating) is the maximum service temperature at which the critical properties of a material will remain within acceptable limits (about 50% after 10 cycles), according to UL testing. Ultimately RTI is an indication of the material’s properties, but doesn’t consider specific application factors such as stresses that are inherently molded into a part before an external load is applied, chemical exposure, part thickness, etc. The only reliable method to predict part performance is to test a prototype part under actual conditions.There are up to three independent RTI ratings:1. Electrical measures dielectric strength 2. Mechanical with Impact measures tensile impact strength 3. Mechanical without Impact measures tensile strength

For Polycase’s standard flame-retardant ABS, the stated RTI temperature is 80 degrees C (176 F). However, just like my fellow drivers CAN drive 10 miles over the limit, it’s probably safer to drive at a slower rate than that. Therefore, I suggest coming in under that temperature, to be safe, using 70 degrees C as the maximum service temperature.What situations have you found it best to stay below the posted threshold?