- URL

Share

When you’re planning to house electrical wiring in a junction box or waterproof enclosure, you will need to adhere to the National Electrical Code (NEC). At Polycase, we offer products designed to meet industry and electrical safety codes.

What Is NEC Code?

The NEC is a standard guideline for electrical installation and safety practices in the United States. The NEC provides guidelines for installing electrical wiring, equipment and other electrical components to ensure that all electrical systems in the United States are installed safely and properly.

Every three years, the NEC is updated to keep up with technological advancements and changes in electrical safety standards. The code is then updated by a panel of experts in the electrical industry to reflect the latest and safest practices.

Complying with the NEC is necessary to minimize the risk of electrical fires and other hazards. It is important to adhere to the NEC; in fact, it is required by local and state laws. Violations could result in fines, penalties and legal action.

What Are the NEC Requirements for Junction Boxes and Enclosures?

The NEC has outlined specific requirements for junction boxes to ensure the safety and proper installation of electrical wiring systems. Here are some of the requirements that your business will need to follow.

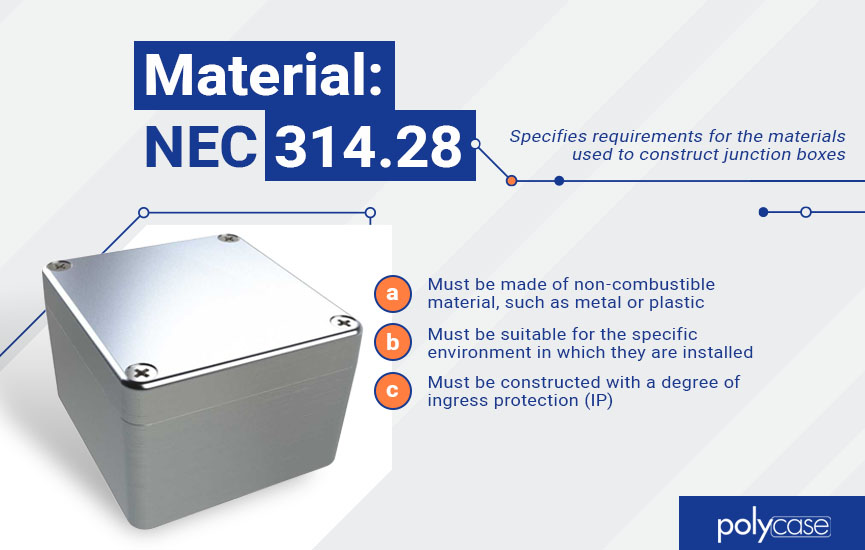

Material: NEC 314.28

Section 314.28 specifies the requirements for the materials used to construct junction boxes. Junction boxes must be made of non-combustible material, such as metal or plastic. They must be suitable for the specific environment in which they are installed. For example, if you need to install your junction box in a damp or wet location, it must be rated for use in wet locations.

Junction boxes must be constructed using corrosion-resistant materials like stainless steel or aluminum. The metal must be thick enough to support the electrical conductors and devices inside the box.

If you use non-metallic junction boxes, they have to be constructed using materials suitable for the electrical environment. This includes materials resistant to UV light, moisture and other environmental factors.

Junction boxes must be constructed with a degree of ingress protection (IP). This includes protection against dust, dirt and other foreign materials that could damage electrical equipment.

Volume Size: NEC 314.16

Section 314.16 specifies the minimum volume size of junction boxes required for various types of electrical conductors. The volume size of a junction box is measured in cubic inches. It is determined based on the number and size of conductors within the box. You must also consider the volume of devices and fittings installed within the box, such as switches or receptacles.

The code specifies the minimum box size you will need for different wire sizes and the minimum volume size of the box required for different numbers of conductors. For example, a box that contains three to six conductors requires a minimum volume of 18 cubic inches, while a box that contains seven or eight conductors requires a minimum volume of 20 cubic inches.

Accessibility for Hazardous Locations: NEC 370-29

Section 370-29 outlines the requirements for junction boxes used in hazardous locations. Junction boxes must be constructed of approved materials for these locations and be designed or sealed to prevent the escape of flammable gases or vapors from the box. Also, junction boxes are required to be grounded to prevent the buildup of static electricity, which could ignite flammable gases or dust.

You must clearly mark your junction boxes with the appropriate hazardous location classification and any other necessary information, like the maximum temperature rating. You can’t conceal junction boxes in ceilings, walls or non-accessible attics and under-floor areas. In addition, they should not be placed in areas where flammable gases, vapors or dust are present in an amount that could result in a fire or explosion.

Accessibility for Non-hazardous Locations: NEC 314.29

Section 314.29 specifies the requirements for junction boxes used in non-hazardous locations. Junction boxes should be accessible for inspection, maintenance and repair jobs. The location must allow for safe operation and maintenance and be free from any obstructions.

Junction boxes must be securely supported to prevent them from coming loose or moving. In addition, they have to be supported by framing, clamps or other similar supports.

Box covers must be securely fastened to prevent accidental contact with live conductors. The covers should be closed with screws or something similar. They should press firmly against the surrounding surface and extend past the edge by no more than 1/8 inch.

Grounding: NEC 250.110

Section 250.110 outlines the grounding requirements for electrical equipment, including junction boxes. Junction boxes must be grounded to provide a path for fault current to return to the source and to prevent electrical shock. Using an approved grounding method, you must connect the grounding conductor to the junction box.

If the junction box has metal parts not intended to carry current, you must bond these parts to the grounding system. The grounding conductor must be continuous and unspliced. It must also be sized according to the size of the junction box.

Metal junction boxes are required to be grounded by connecting the grounding conductor to a grounding screw or other approved grounding method. You must install the grounding screw in a threaded or factory-made hole.

Non-metallic junction boxes, such as plastic enclosures, should be grounded by connecting the grounding conductor to a grounding clip or other approved grounding method. You must install the grounding clip in a factory-made hole or other suitable location.

Clearance: NEC 110.26

Section 110.26 specifies the requirements for the clearance area around electrical equipment, including junction boxes. Section 110.26(A) requires a clear space of at least 30 inches wide by 36 inches deep. The required depth of the working space is determined by the equipment that is being installed. The minimum depth is 36 inches deep.

You must provide a minimum working space with 3 feet of clearance in front of and around electrical equipment for safe operation and maintenance. The working space must be clear and unobstructed and extend from the floor to the required height. The box has to allow a 90-degree opening of equipment doors.

The required height of the working space is determined by the voltage of the equipment that is being installed. There must be a minimum headroom clearance of 6 feet.

The required width of the working space is determined by the size of the equipment that is being installed. The minimum width requirement is 30 inches wide.

Is It Against NEC To Cover Junction Boxes?

No. As long as the cover meets certain requirements, it’s fine to cover a junction box. The NEC requires that junction box covers be accessible, which means you should be able to remove them without damaging the building structure or finishes. You should also have safe access to the electrical connections inside the junction box for maintenance or repairs.

Junction box covers must be made of non-combustible materials, such as metal or plastic. Also, they must not be covered by any building finish, such as drywall or plaster, unless they are designed to be flush-mounted.

The covers must be large enough to cover the box completely and overlap the box by at least 1/4 inch on all sides. In addition, the covers must be securely fastened to the box using screws or other similar methods. Finally, if the junction box contains splices or other connections, you must label it appropriately.

Do NEMA Enclosures Have NEC Codes?

The NEC does not have specific requirements for NEMA (National Electrical Manufacturers Association) as these enclosures are separate organizations that set standards for electrical enclosures. However, the NEC requires installing electrical enclosures, including NEMA enclosures, in a way that is safe and compliant with code requirements.

How Do NEMA and NEC Codes Differ for Enclosures?

NEMA and NEC are two separate organizations that provide guidelines for different aspects of electrical installations.

NEMA standards:

- Focus on the construction and performance of electrical enclosures

- Cover a wide range of enclosures, including industrial, commercial and residential applications

- Provide detailed specifications for enclosure materials, construction, finishes and performance ratings

- Are voluntary and are not enforced by law

On the other hand, NEC requirements:

- Focus on the safety and compliance of structures with electrical codes

- Apply to all electrical installations, including those that use enclosures

- Provide more general guidelines for enclosure installation, clearances, grounding and protection

- Are adopted into law by state and local governments and are enforced through electrical inspections

Purchasing a Polycase Enclosure for Your Business

When you purchase a junction box, waterproof enclosure, plastic enclosure or NEMA enclosure for your business, Polycase can ensure that the enclosure you select will abide by NEC and NEMA codes. Our waterproof and plastic enclosures also meet IP requirements. Find out more about our high-quality junction boxes and enclosures by browsing our website.

Image Credits

Ri team/Shutterstock.com

VITALII BORKOVSKYI/Shutterstock.com

Chalermsak/Shutterstock.com

0 Comment