- URL

Share

In the 21st century, our world is constantly humming with electromagnetic interference (EMI). The millions upon millions of devices and appliances we use every day create these electromagnetic disturbances, as do certain natural phenomena. Humans can’t feel this interference, but many types of important electrical and electronic devices can.

When a machine receives too much interference, it can lead to serious problems in performance and reliability. That’s why most device manufacturers design their products with built-in systems that reduce or eliminate the effects of EMI. These EMI shielding systems employ a wide variety of methods to protect our most important devices from interference.

If you design, manufacture or use devices sensitive to EMI, it’s important to have a basic knowledge of how this phenomenon works and how to counteract it. In this article, we’ll look at the fundamental principles of EMI and the most common types of interference. Then, we’ll preview some of the Polycase enclosures that offer built-in EMI shielding for sensitive devices.

What Is EMI?

EMI, defined in the simplest terms, is the transmission of unwanted electromagnetic radiation to an electrical or electronic device. These signals interfere with a device’s operation and can cause significant harm. EMI can originate from many different sources, both natural and man-made.

Common household and workplace devices are among the most common sources of EMI. Some devices, such as TV remote controls, create relatively small and weak fields. Others, like microwave ovens and smartphones, create more powerful ones. When these fields come into contact with other devices, they can create detrimental interference.

Furthermore, EMI doesn’t even have to originate from an outside source. Internal EMI, in which one of a device’s components generates interference in another component, is another common source of problems. Upstream problems with the quality and conditioning of power sources are also frequent culprits, and these two types of internal EMI working together can create real headaches for device designers and builders.

As if those sources didn’t cause enough problems, nature itself can create EMI. Atmospheric phenomena like thunderstorms and solar storms are natural emitters of electromagnetic radiation, and they can have similar detrimental effects on electrical devices.

You might also hear about radio frequency interference (RFI) in the context of discussions about EMI, as the two terms are often used together or even interchangeably. RFI is a subset of EMI that occupies the band of the electromagnetic spectrum known as the radio frequency (RF) band. It’s an especially common type of interference because so many devices, including many common types of power switching equipment and electric motors, can emit on frequencies in this spectrum.

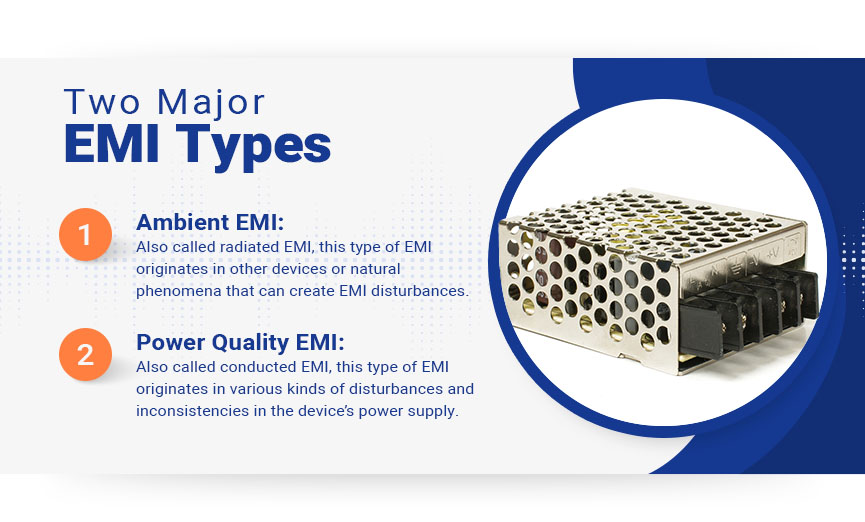

The Two Major Types of EMI

Two specific types of EMI are responsible for the majority of interference in electrical and electronic devices. Knowing the difference between these two types and how to tell them apart will help pinpoint the source of EMI problems in your devices and allow you to more effectively evaluate solutions.

- Ambient EMI: Also called radiated EMI, this type of EMI originates in other devices or natural phenomena that can create EMI disturbances. This includes a huge range of the aforementioned common household and workplace devices, as well as natural events like solar magnetic storms and lightning strikes.

- Power Quality EMI: Also called conducted EMI, this type of EMI originates in various kinds of disturbances and inconsistencies in the device’s power supply. These include power interruptions, voltage sags and spikes and line noise.

Some subsets of EMI affect devices and systems in certain application types. Three of the most important application-specific EMI types are:

- Intentionally Generated EMI: This type of EMI originates from phenomena like nuclear electromagnetic pulses (NEMPs) the military use to disrupt device operations. Intentionally generated EMI is typically only a major concern in specific applications, such as military and critical infrastructure systems, but it often requires the most intensive precautions to combat.

- Railroad and Mass Transit System EMI: The electrical systems used to power today’s rail transit are susceptible to special types of EMI. Third rail shoes, train control systems, other trains and electrical supply lines can all create EMI, with potentially hazardous consequences for the safe operation of mass transit systems.

- Medical Device EMI: Hospital and clinic environments are full of devices that can both emit and receive EMI, including patient monitoring systems, drug pumps, imaging machines and many other common devices. This creates a high level of ambient EMI in many healthcare settings, and the increasing deployment of medical IoT devices means the phenomenon is likely to become even more prevalent.

Consequences of EMI

EMI and RFI can affect many different technologies and cause a wide variety of problems. Common performance issues EMI can cause include:

- Distortion of video and audio signals

- Difficulty in establishing wireless connections

- Interference with control and monitoring systems

- Overheating and fires (in extreme cases)

- General technological malfunctions and difficulties

These are some types of devices especially vulnerable to EMI:

- Medical devices

- Wi-Fi routers

- Computers

- GPS systems

- Smartphones

- Baby monitors

- Walkie-talkies

- Broadcast television

- AM and FM radio

Of course, the irony is many of the devices most vulnerable to EMI are the same devices most susceptible to it. Part of what’s often so frustrating about troubleshooting EMI issues is the phenomenon is a two-way street, with devices able to both transmit and receive interference.

Understanding EMC Requirements

The U.S., European Union and many other countries have regulations known as electromagnetic compatibility (EMC) standards that govern EMI emissions from electrical devices. EMC standards mandate that devices capable of emitting EMI can’t interfere with certain critical technologies, such as medical devices and emergency alert systems.

The specifics of EMC standards can vary widely, so it’s important to be familiar with which set of common EMC standards your device will need to comply with. Some contain basically the same core information, while other standards, such as those used in aerospace or medical equipment, are highly specialized to their applications. Standards also vary by country, although some countries have harmonized theirs with other nations to facilitate trade.

Order an Electrical Enclosure Box Today!

EMI Shielding: Common Tools and Techniques

EMI shielding is the practice of using various countermeasures to protect electrical and electronic devices from EMI. Some common methods of EMI shielding include:

- Many electrical device designers will specify an electrical enclosure box made from a conductive metal like aluminum or steel due to these metals’ natural EMI protection. A properly constructed metal enclosure can absorb and redirect the interference rather than allowing it to reach the device inside. Aluminum, copper, silver and various kinds of steel are all metals commonly used for their natural resistance to EMI.

- Equipping an electronics enclosure with an EMI-shielded gasket can help further mitigate EMI in a device. These gaskets are made from standard materials like neoprene, but they contain conductive metallic linings like expanded aluminum or wire mesh that turn the gasket into a conductive barrier against EMI.

- Conductive spray coatings are another option for adding EMI resistance to an enclosure. These coatings use highly conductive metals like copper or nickel in a spray-on format that can be applied to non-conductive materials like polycarbonate, providing an effective way to add EMI resistance to a variety of device enclosure types.

- Using EMI-shielded cables can be an effective way to combat the many EMI-transferring properties of electrical cables. Cables can both emit and receive EMI, and shielded cables can reduce vulnerability to both. That makes them an effective and important part of the solutions toolbox for improving a device’s EMI resistance.

- Many device designers add electronic filter circuits to a device’s most important components to reduce their vulnerability to EMI. The large range of filter designs available, and the fact filters can be calibrated to accept certain frequencies and reject others, makes them a highly versatile and popular choice for controlling EMI in all kinds of devices.

- EMI mitigation techniques are often an effective complement for shielding. These can include anything from orienting a device in a different direction to placing a wall between two devices. In some cases, where EM radiation levels are relatively low, these techniques may be sufficient to control interference.

Important Things to Know About EMI Shielding

EMI is a complex phenomenon that can interact in unexpected ways with various devices, materials and circuit pathways. These are a few of the most important facts you should know about EMI and RFI shielding:

- Some devices, such as Wi-Fi routers and key fobs, need the ability to wirelessly transmit RF signals. Metal enclosures and other enclosures that block EMI can also block the transmission these devices rely on. For these applications, polycarbonate enclosures are often a better choice.

- An enclosure’s shielding performance can be compromised by seams or gaps that haven’t been properly secured. Even relatively small apertures in the enclosure can act as antennas that allow EM radiation to leave or enter. To combat this, enclosure designers will often specify enclosures with continuous body designs that allow a minimal amount of EM radiation to escape.

- Grounds are often a source of persistent EMI, as the frequencies in a high-impedance ground can create a so-called “noise voltage” that’s tough to eliminate. Using low-impedance grounding techniques is typically the best way to control ground EMI.

EMI Shielded Enclosures from Polycase

Many of the most common use cases for Polycase enclosures require EMI protection. Our customers use our enclosures for everything from industrial controllers to scientific instruments, and there’s no room for interference in these highly sensitive and delicate applications.

That’s why Polycase offers a full range of enclosures with EMI shielding features. Many of our leading indoor and outdoor enclosure models, such as our stainless steel and aluminum enclosures, provide an inherent level of EMI/RFI attenuation. That makes them an outstanding choice for EMI-sensitive devices. Below, we’ll quickly look at some of the top options Polycase offers for EMI and RFI shielded enclosures.

- SA Series: Constructed from EMI-resistant 304 stainless steel, these NEMA 4X enclosures include a locking hinged door and a protective waterproof gasket. Each model is an outstanding choice for its combination of aesthetics and performance..

- SB Series: The SB Series are NEMA 4X enclosures fabricated from powder-coated 16-gauge carbon steel, and they also offer strong protection against all kinds of EMI. These models are popular among customers who need EMI protection and superior durability at an economical price point.

- AN Series: For some of our stoutest NEMA 6P protection combined with natural EMI resistance, the AN Series aluminum electronics enclosures are a perfect choice. Their ADC-12 diecast alloy aluminum protects your devices from harmful interference.

- AL Series: The indoor equivalent to the AN Series, the AL Series are ADC-12 diecast aluminum enclosures designed as an ideal choice for small instrument enclosures and potting boxes. They’re designed to provide excellent EMI protection while offering the polished and professional look of diecast aluminum.

- EX Series: These extruded aluminum IP66 enclosures are among Polycase’s top choices for desktop and consumer electronics applications in which EMI shielding is often required. The EX Series models’ extruded aluminum construction gives them natural EMI resistance, and their slim form factor makes them a best-in-class choice for indoor electronics enclosures.

Need a Stainless Steel Enclosure? We Have Those, Too!

Polycase is always happy to answer our customers’ questions about enclosure features, specifications and more. Interested in learning more about how our enclosures can protect your devices from harmful interference? Call our experts at 1-800-248-1233 or contact us online for more information.

Image Credits

Ihor Biliavskyi/Shutterstock.com

yanik88/Shutterstock.com

Proxima Studio/Shutterstock.com

Zyn Chakrapong/Shutterstock.com

Peter Sobolev/Shutterstock.com

0 Comment